June 8th 2024

How Far Can a Plane Fly if Both Its Engines Fail?

It may sound surprising but it’s not uncommon for jets to descend at what a pilot calls ‘flight idle’.

- Hugh Morris

guvendemir/Getty Images

In 2001 a plane carrying 293 passengers and 13 crew lost power in both its engines over the middle of the Atlantic Ocean.

Unbeknown to the pilots of Air Transat Flight 236, the aircraft bound for Lisbon had been leaking fuel ever since it left Toronto six hours earlier. Having lost the first of two engines, Captain Robert Piche declared a fuel emergency and announced to Air Traffic Control his intention to divert to the Azores. Ten minutes later the second engine sputtered to a stop.

Piche and his first officer, Dirk DeJager, with more than 20,000 hours of flight experience between them, proceeded to glide the Airbus A330, without any power, for 19 minutes – covering some 75 miles – until landing hard at Lajes Air Base.

The plane, which was forced to perform a series of turns and one full circle to lose the necessary altitude, bounced on the runway before coming to a stop. No lives were lost and the incident remains the furthest flown by a passenger jet without engine power in aviation history.

The tale of Air Transat Flight 236 acts as a reminder that even if both engines fail on your flight, there’s still a decent chance everyone will be reach the ground safely. This should be of particular comfort to anyone feeling queezy after reading about things like the 2021 United Airlines flight that suffered a right engine failure shortly after takeoff – causing large pieces of debris to fall from the sky, narrowly missing a home.

How can a plane fly without any engines?

“While it may surprise you, it’s not the least bit uncommon for jets to descend at what a pilot calls ‘flight idle’, with the engines run back to a zero-thrust condition,” says pilot and author Patrick Smith in his book Cockpit Confidential. “They’re still operating and powering crucial systems, but providing no push. You’ve been gliding many times without knowing it. It happens on just about every flight.”

Smith explains that idle thrust is doing harder work than engines cut out altogether, but not by much. He likens it to coasting down a hill in a car with the clutch down.

Different aircraft have different glide ratios, meaning they will lose altitude at different rates, affecting how far they can fly without engine thrust. For example, if a plane has a lift to drag ratio of 10:1 then that means for every 10 miles of flight it loses one mile in altitude. Flying at a typical altitude of 36,000 feet (about seven miles), an aircraft that loses both engines will be able to travel for another 70 miles before reaching the ground.

Smith continues: “Total engine loss is about as probable as a flight attendant volunteering to give you a shoe-shine, though it has happened.

“Culprits have included fuel exhaustion, volcanic ash and impacts with birds. In several of these incidents, crews have glided to a landing without a single fatality or injury.”

Has total engine loss happened to many planes?

One such incident took place in 1982, when a British Airways 747 on its way to Auckland passed through a cloud of volcanic smoke courtesy of Mount Galunggung, West Java.

“I don’t believe it – all four engines have failed,” were the words of the flight engineer as one by one all four of the 747’s engines sucked in the thick ash.

With a glide ratio of about 15:1, the crew realised the aircraft had a shot at gliding for 23 minutes, over 91 miles, but just as it approached Jakarta, where it was to perform an emergency landing, one of the engines restarted, then another, before all four were firing again, and the plane landed safely.

The incident featured one of the greatest tannoy announcements by a pilot in the history of aviation. Captain Eric Moody addressed the passengers: “Ladies and gentlemen, this is your captain speaking. We have a small problem. All four engines have stopped. We are doing our damnedest to get them going again. I trust you are not in too much distress.”

At A Glance: What is ETOPS?

ETOPS (Extended Operations) is, broadly speaking, the practice of ensuring that a long-haul aircraft’s route always passes within a certain distance from a diversion airport, measured in flight time. ETOPS accompanied with a number, ETOPS120 for example, refers to the flight time away from any diversion airport, and is assigned to each aircraft.

There are different levels of ETOPS, according to how many engines an aircraft has, a key factor in how far it might be able to fly should one or more engines fail. For example, some aircraft would be subject to a route that is never more than 120 minutes from a diversion airport, whereas some might be permitted a 180 minute restriction.

In informal aviation circles, ETOPS means “Engines Turn Or Passengers Swim”, though the term has no bearing on whether aircraft are travelling over water or land.

Can it happen to modern aircraft?

In 2017 the air-worthiness of the world’s largest passenger jet, the A380 – minus one of its engines – was tested when an Air France flight was forced to make an emergency landing in Canada after one of its engines suffered a rather spectacular malfunction.

The A380’s ability to fly with three engines was tested further when the aircraft had to be repatriated, back across the Atlantic, with just three working engines.

But perhaps the most famous occasion a commercial aircraft was forced to glide after losing all thrust was the so-called “Miracle on the Hudson”, when Captain Chesley Sullenberger landed an Airbus A320 on the Hudson River after a flock of Canada geese had taken out both its engines.

Patrick Smith praised Sully, but pointed out that he was just doing his job.

“Nothing [Sully and his co-pilot Jeffrey Skiles] did was easy, and a successful outcome was by no means guaranteed,” he says. “But they did what they had to do, what they were trained to do, and what, presumably, any other crew would have done in that same situation.”

Given that a plane can fly without any engine power, it goes without saying that if just one engine cuts out during a flight there is very little risk.

Indeed, as Smith reminds us, airliners are designed so that should an engine cut out during take-off, a sole motor will be enough to get the plane off the ground – a phase that requires more thrust than simply cruising.

“Bigger planes have incredibly powerful engines and fancy high-lift devices (flats, slats and such) that allow them to take off and land at relatively low speeds,” he says.

So, while pilots will likely seek an emergency diversion should one of their engines fail (as governed by ETOPS – see above), which involved heading to the nearest airport, passengers need not worry.

April 19th 2024

| Electric Vehicles Have Been Around Since the 19th Century: Timeline |

| Electric vehicles were some of the earliest automobiles ever invented—and, unlike early gas-powered cars, they didn’t require a crank to start the engine. |

| Read More |

March 21st 2024

Glenfinnan Viaduct

Published: 17th November 2020, last updated: 14th September 2023

The Glenfinnan Viaduct is a whopping 380m long, making it the longest concrete railway bridge in Scotland, and it crosses the River Finnan at an impressive height of 30m.

If you are a history buff, you may be familiar with this structure due to the area’s significance in the plight of the Jacobites, or if movies are your thing you might be more likely to think of it as ‘the Harry Potter bridge’. Either way, or even if you have never heard of the Glenfinnan Viaduct before, there is no denying that it is an incredible piece of architecture and that the stunning surrounding scenery is rival almost to none. Read on to find out more.

What is a Viaduct?

In case you aren’t familiar with the term, a viaduct is a type of bridge, one that particularly stands out because of it’s configuration of arches, piers, or columns which support a long elevated stretch of railway or road.

Typically a viaduct is used to allow passage over a low lying valley or river or other kind of obstruction, by connecting two points of roughly equal elevation. It is usual to see a structure built with a series of arches of roughly equal length ,the symmetry of which can often appear extremely grand.

The term viaduct is derived from the Latin via for road and ducere, to lead.

The Hamlet of Glenfinnan

The Hamlet of Glenfinnan is located in the Lochaber area of the Highlands of Scotland. It sits at the head of Loch Shiel, which stretches south west for 20 miles to Acharacle.

Yes, most of the visitors to the area are here to make the most of the attractions in the shape of the Glenfinnan Viaduct itself, as well as the Glenfinnan Monument and the nearby Visitor Centre, but once here it is impossible to ignore the breathtaking natural scenery too.

A stroll through the ancient Caledonian pines at Glenfinnan gives you the perfect opportunity to discover a variety of wildlife, including darting dragonflies, the oldest and fastest insects in the world, as well as tiny butterflies, secretive otters and soaring golden eagles.

The Glenfinnan Monument

The area has a historical claim to fame because in 1745 it was here in Glenfinnan that the Jacobite rising began here when Bonnie Prince Charlie raised his standard on the shores of Loch Shiel. This is why seventy years later in 1815, the Glenfinnan Monument was built at the head of the loch to commemorate the historic event.

By this time the Jacobite forces were no longer a threat to the government, and it was Alexander Macdonald of Glenaladale who built the 18m structure. In 1938 the statue passed into the care of the National Trust for Scotland, and it is a popular tourist attraction to this day.

Thousands of people flock to look upon the solemn looking stone Highlander, referred to at the point of commission as Charles Edward Stuart, but who now serves as a poignant reminder of all of the clansmen who gave their lives to the Jacobite cause.

Construction of the Glenfinnan Viaduct

The building of the Glenfinnan Viaduct started in 1897 and was completed in 1898, although the railway line extension from Fort William to Mallaig was not actually completed in full and opened until 1901. Until the line was fully operational the Glenfinnan Viaduct was just used to transport materials across the valley. The total cost for building this enormous bridge was £18,904.

Robert McAlpine & Sons were the contractors taken on to build the structure, with Simpson & Wilson working as the engineers. Robert McAlpine & Sons was headed by Robert McAlpine, who was informally nicknamed “Concrete Bob” thanks to his innovative use of mass concrete. Concrete had to be used due to the difficulty of working the hard schist in the area.

The Glenfinnan Viaduct is built from mass concrete, which unlike reinforced concrete does not contain any metal reinforcement. It is formed by pouring concrete, typically using fine aggregate, into formwork, resulting in a material very strong in compression but weak in tension.

If you are to visit the bridge at attempt to count the arching semicircles, you will find that there is a total of 21, each spanning 15 metres. It is the longest concrete railway bridge in Scotland at 380 m. It crosses the River Finnan at a height of 30 m, or a whopping 100 feet if you work in old money measurements! The West Highland Line it carries is made up of a single track, and the viaduct between the parapets stretches 5.5 metres wide.

The Horse Legend of the Glenfinnan Viaduct

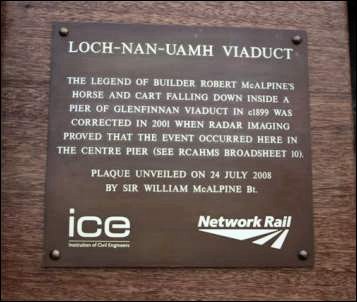

It is a long-established legend that a horse had fallen into one of the piers during construction of the Glenfinnan Viaduct in 1898 or 1899. There is in fact a plaque commemorating the incident at Glenfinnan Train Station. Supposedly the horse belonged to ‘Concrete Bob’ McAlpine of the construction company and when it horrifically fell, and it was said to dragged it’s cart down along with it.

In 1987 Professor Roland Paxton MBE, ascertained that there were only two piers large enough to be the location of this incident, and he used a fish-eye lens camera inserted through specially bored holes, only to discover that there was no evidence of a horse or cart.

Then Professor Paxton heard that local landowner Mr E.D. MacMillan had remembered from local hearsay in his father’s time that the accident had in fact occurred at the Loch nan Uamh Viaduct, which is also part of the West Highland Line.

By 2001, technology had moved on so much that state-of-the-art scanning exercise was able to be carried out at the Loch nan Uamh Viaduct. Many hours of work were involved in the process, involving transmitting radio waves through walls up to 9 feet thick, and monitoring and interpreting the results. Incredibly, it was able to be clearly seen that there was in fact the remains of a horse, standing vertically against the east wall above the wreck of a cart. This would imply that it was the loaded cart that fell first into the cavity, dragging the horse with it.

Trains over the Glenfinnan Viaduct

The railway line which operates over the Glenfinnan Viaduct is the West Highland Line. The West Highland Line connects Fort William and Mallaig, and was a crucial artery for the local fishing industry and the highlands economy in general, which suffered enormously after the Highland Clearances of the 1800s.

The line is used nowadays by passenger trains carrying people visiting Scotland, and is operated by ScotRail between Glasgow Queen Street and Mallaig, usually diesel multiple units. Additionally, in the summer, the heritage Jacobite steam train operates along the line. It is a popular tourist event in the area, and the viaduct is one of the major attractions of the line. Find out more about the Jacobite Steam Train here.

It is no wonder really that this journey has been described as the greatest railway journey in the world by those who have encountered it when visiting Scotland. As well as the excitement of crossing over the Glenfinnan Viaduct itself, the 84 mile round trip takes you past a list of impressive extremes, including:

- the highest mountain in Britain, Ben Nevis,

- Britain’s most westerly mainland railway station, Arisaig

- the deepest freshwater loch in Britain, Loch Morar

- the shortest river in Britain, River Morar

- the deepest seawater loch in Europe, Loch Nevis!

The Glenfinnan Viaduct Viewpoint

The Glenfinnan Viaduct viewpoint is not defined as a particular spot, rather any spot along the path. It is typical to find at least a few tourists already waiting for the train to come by at most of the crossing times, but luckily there’s plenty of space so you shouldn’t have trouble finding a good viewing spot.

The easiest route to access Glenfinnan (apart from via the train of course!) is via the town of Fort William, and this car journey will take you around 30 minutes. There is also an infrequent bus service from Fort William to the Glenfinnan visitor centre, or there are a number of tour operators operating guided coach tours throughout the area.

You can find out more about some of these tours HERE

March 8th 2024

What Boeing’s Door-Plug Debacle Says About the Future of Aviation Safety

For a flight to be imperiled by a simple and preventable manufacturing or maintenance error is an anomaly with ominous implications.

By: John Downer

On January 6, as Alaska Airlines Flight 1282, a Boeing 737 MAX 9, was climbing out of Portland, a large section of the aircraft’s structure, a fuselage door-plug, broke free in flight. With the plug gone the cabin violently decompressed with a clamorous boom and gale that ripped headrests from their moorings. The mother of a teenage boy seated just in front of the rupture clung to him as his shirt was torn from his body and sucked into the void.

Nobody died in the harrowing incident, somewhat miraculously, but it was a very close call. If the seats directly next to the failed fuselage section had not been empty, or the seatbelt light had not been lit, the event would probably have been deadly.

Failures in modern jetliners are extremely uncommon events in general, but even in this context, the failure looks unusual and concerning. Definitive explanations for why it occurred will take time, but preliminary reports strongly indicate that its proximate cause was shockingly mundane: It seems Boeing, or one of its contractors, simply failed to secure the plug correctly. The errant door-plug appeared to be missing crucial bolts when it was discovered in a residential neighborhood, and subsequent inspections have reportedly revealed improperly bolted plugs on other fuselages. If this theory is confirmed, then it will be the sheer ordinariness of this failure that sets it apart. This is because when jetliners fail for mechanical reasons, those reasons tend to be much more complicated and interesting (at least from an engineering perspective). For a flight to be imperiled by a prosaic and eminently avoidable manufacturing or maintenance error is an anomaly with ominous implications.

To understand what I mean here, it helps to put the incident into context, and for that, it helps to step back and think briefly about the inherent difficulties of making jetliners as reliable as we have come to expect. Extreme reliability is hard, especially in complex technologies that operate in unforgiving environments. This is intuitive enough. But the nature of the challenges it poses, and the manner in which the aviation industry has managed those challenges, are both widely misunderstood.

The extreme levels of reliability that we expect of jetliners poses meaningfully different challenges than the “normal” reliability we expect of almost any other system. In essence, this is because designing a system that won’t fail very frequently requires that engineers understand how it will function — and thus fail to function. Engineers can’t just wait for them to crash to learn how reliable they are! The effort required to achieve extreme reliability doesn’t scale proportionally with the desired level of safety. (Such that, for instance, doubling the reliability of a complex system requires more than double the effort.)

Not even the most exhaustive tests and models could hope to capture every subtlety of a jetliner’s real-world performance over billions of hours of operation.

To appreciate the latter relationship, consider the work of building a system that is reliable 99.99 percent of the time (i.e., one that fails no more than once in every 10,000 hours of operation). To achieve this, engineers need to understand how the system will behave over that period of time: the external conditions it might face, how its many elements will interact with those conditions, and a great deal else. And for that they need abstractions — theories, tests, models — that are representative enough of the real world to accurately capture the kinds of eventualities that might occur only once in every 10,000 hours. Such representativeness can be challenging, however, because the real world is “messy” in ways that engineering abstractions never perfectly reproduce, and a lot of unexpectedly catastrophic things can happen in 10,000 hours. An unusual environmental condition might interact with a material in an unanticipated way, causing it to corrode or fatigue. An obscure combination of inputs might cause essential software components to crash or behave erratically. We don’t know what we don’t know, as the old truism goes, so these kinds of things are difficult to anticipate.

Now consider what happens as the reliability required of the system rises from 99.99 percent to 99.999 percent. To achieve this new benchmark engineers need to account for eventualities that might occur not every 10,000 hours, but every 100,000 hours. And so it goes; each new decimal in this “march of nines” represents an order-of-magnitude rise in the obscurity of the factors that engineers need to capture in their abstractions and accommodate in their designs. With each increment, therefore, it becomes increasingly likely that expert’s reliability calculations will be undone by something significant hiding in their understanding of how the system functions: some property, or combination of circumstances that nobody thought to test. (Elsewhere, I have proposed we call such failures “rational accidents.” Partly because they arise from rationally-held but nevertheless erroneous beliefs, and partly because it is rational, epistemologically, to expect them to occur.)

This is the context in which we should understand the reliability of modern jetliners. Viewed through the lens of epistemological uncertainty and its hidden dangers, civil aviation’s safety record over the last few decades is little short of astonishing. The rate of airliner accidents attributable to technological failure implies that their critical systems have mean-times-to-failure not of 10,000 hours, and not even of 100,000 hours, but north of a billion hours. When reckoning with failures over this kind of timescale, even extraordinarily rare factors can become critical engineering considerations: Unexpected interactions or phenomena that might only show up with a particular phase of the moon or alignment of the stars. As a 20th-century engineering achievement, the sheer ordinariness and tedium of modern air travel is on par with the exceptionality and drama of NASA landing on the Moon. And insofar as the laurels for this achievement should be laid at the feet of any one organization, then it has to be Boeing.

The process by which Boeing and its peers achieved this lofty reliability is widely misrepresented and misunderstood. We have long been conditioned to think of engineering as an objective, rule-governed process, and aviation reliability is firmly couched in this language. So it is that the awesome mundanity of modern flight is ostensibly built on ever more detailed engineering analyses and rigorous regulatory oversight: standards, measurements, and calculations. Like sausages and scriptures, however, these formal practices look increasingly spurious when the circumstances of their production are examined closely. Not even the most exhaustive tests and models could hope to capture every subtlety of a jetliner’s real-world performance over billions of hours of operation. While rigorous analysis and oversight are undoubtedly vital, their usefulness wanes long before they can deliver the kinds of reliability jetliners demand. We can manage the performance of most systems in this way, but pushing past the limits and uncertainties of our abstractions to achieve the performance we expect of jetliners requires more. Herein lies the true engineering challenge of civil aeronautics, and the reason why the industry is so difficult for new entrants.

Examined closely, the industry achieved this feat by leveraging a series of pragmatic but ultimately unquantifiable practices. Stripped to their essence, these amount to a process of learning from experience. Engineers calculated and measured everything that could realistically be calculated and measured, then they gradually whittled away at the uncertainties that remained by interrogating failures for marginal insights that had eluded their tests and models. They slowly made jetliners more reliable over time, in other words, by using their failures as a scaffold and guide.

This learning process sounds simple, but it was actually a painful, expensive, decades-long grind, which depended for its success on several longstanding and often challenging institutional commitments. For example, it necessitated a costly dedication to researching the industry’s failures and close calls, and an institutionalized willingness to accept findings of fault (something organizations naturally tend to resist). Perhaps most significantly, it depended on a deep-rooted adherence to a consistent and stable jetliner design paradigm: a willingness to greatly delay, or forgo entirely, implementing tantalizing innovations — new materials, architectures, technologies — that, on paper, promised significant competitive advantages.

Securing bolts properly is about the lowest-hanging fruit of high-reliability engineering.

These vital practices and commitments could never be wholly legislated, audited, and enforced by third parties due to the nuanced and necessarily subjective judgments on which they hinged. Regulators could demand that “new” designs be subjected to far more scrutiny than “light modifications” of prior designs, for instance, but they could never perfectly define what constituted a “light modification.” And, while rules could require that special precautions be taken for “safety-critical” components, the “criticality” of specific components would always be a matter of interpretation.

Huge financial stakes were involved in these ungovernable practices and interpretations, so the cultures in which they made were extremely important. The people making strategic decisions at companies like Boeing (not that there are many companies like Boeing) needed to understand the significance of the choices they were making, and to do that they needed to be able to see past the rule-governed objectivity that frames the safety discourse around modern aviation. They had to realize that in this domain, if in few others, simply ticking every box was not enough. They also needed to be willing, and able, to prioritize expensive, counterintuitive practices over shorter-term economic incentives, and justify their decisions to stakeholders without appeals to quantitative rigor. This made aviation-grade reliability a huge management challenge as well as an engineering challenge.

So how does this understanding of aviation reliability help us make sense of Boeing’s recent missteps with its 737? Seen through this lens, the door-plug drama looks highly unusual in that it appears to have been an avoidable error. This is stranger than it seems. On the rare occasions when jetliner failures are attributable to the airplane’s manufacturer, they are almost always “rational accidents,” with root causes that had hidden in the uncertainties of experts’ tests and models. If the insecure plug was due to missing bolts, then this was something else. Securing bolts properly is about the lowest-hanging fruit of high-reliability engineering. It is the kind of thing that manufacturers ought to be catching with their elaborate rules and oversight, before they even begin their “march of nines.”

We should always hesitate to draw large conclusions from small samples, but a failure this ordinary lends credence to increasingly pervasive accounts of Boeing as a company that has gradually lost its way; its culture and priorities increasingly dominated by MBAs rather than the engineers of old. Especially when that failure is seen in conjunction with the 2019 737-MAX disasters, which were also rooted in avoidable design shortcomings, and the “Starliner” space capsule’s ongoing troubles.

This is probably the failure’s real significance: The underlying shift in institutional culture that it represents. Boeing will surely remedy any specific problem with missing or unsecured bolts; it would be truly incredible if that mistake was ever made again. The fact that the mistake was made at all, however, suggests an organization that is decreasingly inclined, or able, to make the kinds of costly, counterintuitive, and difficult-to-justify choices on which it built its exemplary history of reliability. These choices always pertain to marginal, almost negligible, concerns — simply because reliability at high altitudes is all about the margins — so their consequences manifest slowly. But their effects are cumulative and inexorable. A company that is not securing its bolts correctly is unlikely to be making the kinds of strategic decisions that pay dividends in decades to come.

John Downer is Associate Professor in Science and Technology Studies at the University of Bristol, and the author of “Rational Accidents.”

The MIT Press is a mission-driven, not-for-profit scholarly publisher. Your support helps make it possible for us to create open publishing models and produce books of superior design quality.

January 13th 2024

How will the Boeing 737 Max 9 problem affect air travel?

As shocking as the in-flight blowout on Alaska Airlines Flight 1282 was last week, federal officials initially estimated that the problem that caused a gaping hole to open in the plane’s fuselage would be relatively easy to diagnose and fix.

On Tuesday, though, the Federal Aviation Administration said the process will take a bit longer than anticipated. For the time being, all planes configured the same way as Flight 1282 — a recently introduced update to the extremely popular Boeing 737 — will remain grounded.

That means more travelers on United and Alaska airlines will see their flights canceled in the days to come. Here’s what we know so far about the disruption in air travel, when it might end, and what the eventual return of these planes to service might mean for fliers — especially the nervous ones.

Which airplanes are affected?

Flight 1282 was on a custom version of the Boeing 737 Max 9, the latest in a series of revisions designed to enlarge the 737s so they could carry more passengers, and generate more revenue. The Max 9s are almost 9 feet longer than the 737 Max 8s that came out a few years previously, and when they carry the full complement of seats, they require an extra emergency exit between the wings and the tail.

The number of emergency exits required depends on the number of seats, said Robert L. Ditchey, an aviation consultant based in Marina del Rey. But a few airlines ordered a modified version of the Max 9 with fewer seats, dispensing with the need for the extra exits. That means fewer potential tickets sold, but also less maintenance costs associated with the emergency door and the exit slide, he said.

Rather than creating a new fuselage for the alternate version, Boeing used the same one but plugged the holes for the two extra emergency exits with a plate that’s bolted to the frame. That’s the part — known as the door plug — that blew off on Flight 1282 when the plane’s interior was pressurized.

United, Alaska find loose hardware on jets amid probe into Boeing 737 Max 9 blowout

Jan. 8, 2024

Which airlines have the grounded planes?

Boeing won’t disclose its customer list, but Alaska and United Airlines are the only domestic carriers that have been publicly identified as having the modified 737 Max 9s. United says it has 79 Max 9s, and Alaska says it has 65.

The aviation website flightradar24 named three foreign airlines that are operating Max 9s with door plugs — Copa Airlines, Aeromexico and Turkish Airlines.

August 23rd 2023

A Living History of The Humble Paper Airplane

For centuries, paper airplanes have unlocked the science of flight—now they could inspire drone technology.Sarah Wells and Jennifer LemanPublished: Aug 9, 2023

Shinji Suzuki met Takuo Toda in 1999, atop Mt. Yonami in the southern city of Jinseki-Kogen, Japan. Toda, the chairman of the Japan Origami Airplane Association, was there to launch a large paper plane from a tower he had built on the mountaintop for just that purpose.

Toda persuaded the local city council to build the 85-foot-tall tower—with 360-degree views of Mount Daisen, Mount Dogo, and the Hiba Mountains—as a monument to paper airplane hobbyists. The first floor of the tower includes a showcase of precisely folded paper plane models, while the top floor opens into a veritable launch pad. When Suzuki first met Toda, he was launching the almost-seven-foot-long paper plane—modeled after the space shuttle Discovery—off that very flight deck. “He told me that he would like to launch this paper plane from the space station,” Suzuki, now an emeritus professor in aviation at the University of Tokyo, says. “Everybody laughed at him.”

Related Story

Toda’s lofty dream inspired Suzuki to take action, and in 2008, the pair announced a project to launch paper airplanes from the International Space Station (ISS). Critics suggested these planes would burn up on their descent back to Earth, Suzuki says. However, he predicted that with a protective coating and a controlled trajectory, they might actually be able to avoid burning up on reentry into Earth’s atmosphere. Another challenge? Figuring out where exactly the planes would land.

While Suzuki plotted the planes’ journey to the ISS, Toda would chart another path, racking up Guinness World Records for his paper airplane designs. For decades, he’s aimed to break the 30-second record for time aloft of a paper plane. He’s come close multiple times.

At a Japan Airlines hangar near Tokyo’s Haneda Airport in 2009, Toda sent a paper plane soaring for a whopping 26.1 seconds. And he holds the current time aloft record, which he set in 2010 with a rectangular design that lingered in the air for an astonishing 29.2 seconds. There are other records to be broken, too. As of April 2023, a trio of aerospace engineers currently hold the title for longest-distance throw of a paper airplane. Their dart-shaped plane traveled 289 feet and 9 inches, beating the previous record by almost 40 feet.

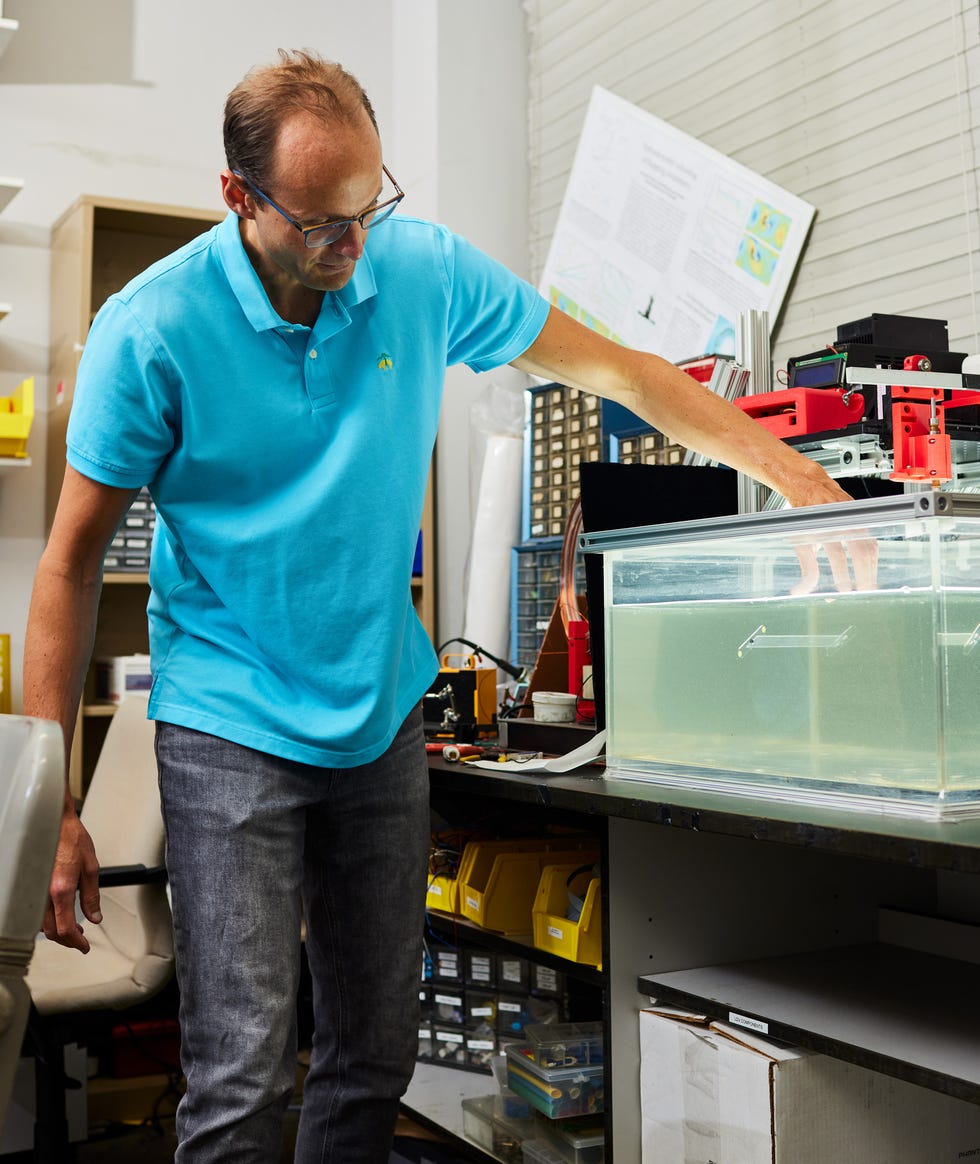

Leif Ristroph, a fluid dynamicist at N.Y.U., tosses a sheet of paper across the room. He and his colleagues test different paper shapes and sizes to see how well they glide. Henry Hung

Advertisement – Continue Reading Below

Henry Hung

Henry Hung

Our obsession with testing the boundaries of folded flight is relatively recent, but our desire to explore and explain the complex world of aerodynamics goes back much further.

Advertisement – Continue Reading Below

Chinese engineers are thought to have invented what could be considered the earliest paper planes around 2,000 years ago. But these ancient gliders, usually crafted from bamboo and paper or linen, resembled kites more than the dart-shaped fliers that have earned numerous Guinness World Records in recent years.

Leonardo da Vinci would take a step closer to the modern paper airplane in the late 14th and early 15th centuries by building paper models of his aircraft designs to assess how they might sustain flight. But da Vinci’s knowledge of aerodynamics was fairly limited. He was more inspired by animal flight and, as a result, his design for craft like the ornithopter—a hang-glider-size set of bat wings that used mechanical systems powered by human movement—never left the ground.

Paper airplanes helped early engineers and scientists learn about the mechanics of flight. The British engineer and aviator Sir George Cayley reportedly crafted the first folded paper plane to approach modern specifications in the early 1800s as part of his personal experimentation with aerodynamics. “He was one of the early people to link together the idea that the lift from the wings picking up the aircraft for stable flight must be greater than or equal to the weight of the aircraft,” says Jonathan Ridley, PhD, the head of engineering and a scholar of early aviation at Solent University in the U.K.

“Over the last 20 years, there’s been an increasing interest in smaller-scale flight.”

More than a century later, before their famous 1903 flight in Kitty Hawk, North Carolina, the Wright Brothers built paper models of wings to better understand how their glider would sustain flight, explains Ridley. They then tested these models in a rudimentary, refrigerator-size wind tunnel—only the second to be built in the U.S.

Paper planes are still illuminating the hidden wonders of flight. Today, these lightweight aircraft serve as a source of inspiration not only for aviation enthusiasts but also for fluid dynamicists and engineers studying the complex effects of air on small aircraft like drones.

At Cornell University, in a lab run by physics professor Jane Wang, PhD, paper gliders plunge, swoop, and flutter through the air. What might look like child’s play to the untrained eye is actually part of a serious experiment conducted by Wang and her colleague Leif Ristroph, PhD, an associate professor of mathematics at New York University. Once the planes land, Wang and Ristroph analyze data from their flight and apply weights to change the balance of these gliders. They hope doing so will help them better understand how lightweight objects soar—something that could one day inform the future of miniature drones and other robotic craft.

Jane Wang sometimes travels to a gorge near Cornell’s Ithaca, NY, campus to conduct her experiments. Henry Hung

The team’s most recent study, published in the Journal of Fluid Mechanics in February 2022, explored the mechanics of gliding and identified new ways for paper gliders to achieve stable flight. Insights gleaned from this research have practical applications, but they also shed light on the aerodynamic principles that keep paper airplanes thrown by enthusiasts up in the air. All planes —powered and unpowered —are controlled by the four forces of flight: lift, weight, thrust, and drag. Lift is the aerodynamic force produced by the forward motion of an object through a fluid—in this case, air. Weight, or the force of gravity, is the opposing force and pulls the airplane toward Earth. Where the engines or propellers on a passenger aircraft generate thrust, the force of a paper plane pilot’s throw gives the aircraft the forward momentum. Drag, caused by the friction a plane experiences as it moves through the air, acts in opposition to thrust.

Traditional airplanes have airfoil-shaped wings with a round leading edge. Air that passes over the wing conforms to its shape. Air flowing above the wing moves faster than air below the wing, forming a low-pressure zone above the wing that generates lift.

“The magic of a paper airplane is that all of these little flight corrections are happening continuously throughout its flight.”

But the wing of a paper glider is flat, and air does not flow smoothly around it. Instead, that air forms a small, low-pressure vortex immediately above the leading edge of the wing. “This little vortex ends up changing a lot of the aerodynamic characteristics of the plane,” Ristroph says. “One thing it does is give the plane a natural stability, meaning that, in principle, it can and will glide.”

As the angle at which a glider’s wing cuts through the air—known as the angle of attack—changes, so too does the size and location of the vortex above the wing. This affects where the center of pressure, or the precise location where lift is focused, lies along the wing and how responsive it is to disturbances. If, for example, the plane encounters a gust that pushes its nose down, the center of pressure will slide forward, pushing the nose back up and into a stable position.

“The magic of a paper airplane is that all of these little flight corrections are happening continuously throughout its flight,” Ristroph says. “The plane is hanging under a vortex that is constantly swelling and shrinking in just the right ways to keep a smooth and level glide.”

The center of pressure for an airfoil, however, is locked in place and does not change with the angle of attack. This means it has trouble self-correcting if destabilized. Ristroph says the team tested this in some of their experiments by folding the sheets into an airfoil. These sheets quickly crashed after brief, erratic flights because they could not stabilize after being perturbed.

Advertisement – Continue Reading Below

This phenomenon changes at different scales, Ristroph adds. For instance, if you were to construct a paper plane the size of a Boeing 747, the vortex above the wing would be much larger and behave differently. “That vortex would not just stay on the plane and sit there, it would jump off, reform again, and do something a little turbulent and a little crazy,” he says. “You might not be able to rely on that vortex to give you stability because it may not always be there.” Conversely, if you created a paper airplane less than, say, a millimeter long, the aerodynamics would change—along with the behavior of that vortex.

Read This Next

The central focus of Ristroph and Wang’s work—and, as their research suggests, the true secret to a stable glide—is identifying and making adjustments based on a glider’s center of balance. The center of balance lies at the point where a plane would be perfectly balanced if suspended in midair. (You can locate the center of balance on a paper airplane by balancing it between the tips of your thumb and forefinger.) For an unfolded sheet of paper like the ones Wang and Ristroph tested, the center of balance is directly in the middle of the page.

The team experimented with tweaking the center of balance by placing strips of copper tape on their paper gliders and studying their flight. If the weights were placed too close to the center of the sheet, the gliders would tumble uncontrollably to the ground. If the weights were placed too far forward, they would immediately nose-dive.

Advertisement – Continue Reading Below

“People can make very, very good paper airplanes now,” Wang says. “It’s a fine art. They build their intuition by making them.”

Through trial and error, they discovered that placing these weights halfway between the middle of the sheet and the leading edge created a stable glide, meaning that even if the glider was disturbed during its flight, it would still be able to right itself. Wang says this discovery was particularly surprising because previous work done on this topic had only ever identified “neutrally stable” modes of flight, which become unstable if perturbed and cannot self-correct.

Ristroph hopes the findings from their work will help engineers design new types of small aircraft that take advantage of passive modes of flight like, say, windsurfing craft that sail high above cities to monitor air quality. “Over the last 20 years, there’s been increasing interest in smaller-scale flight,” Ristroph says. “Small-scale flying robots [could] do things like ride on the wind rather than having some kind of engine or spinning rotors like a helicopter.”

Ristroph tests the aerodynamic properties of a sheet of plastic in a water tank at his N.Y.U. lab.Henry Hung

Advertisement – Continue Reading Below

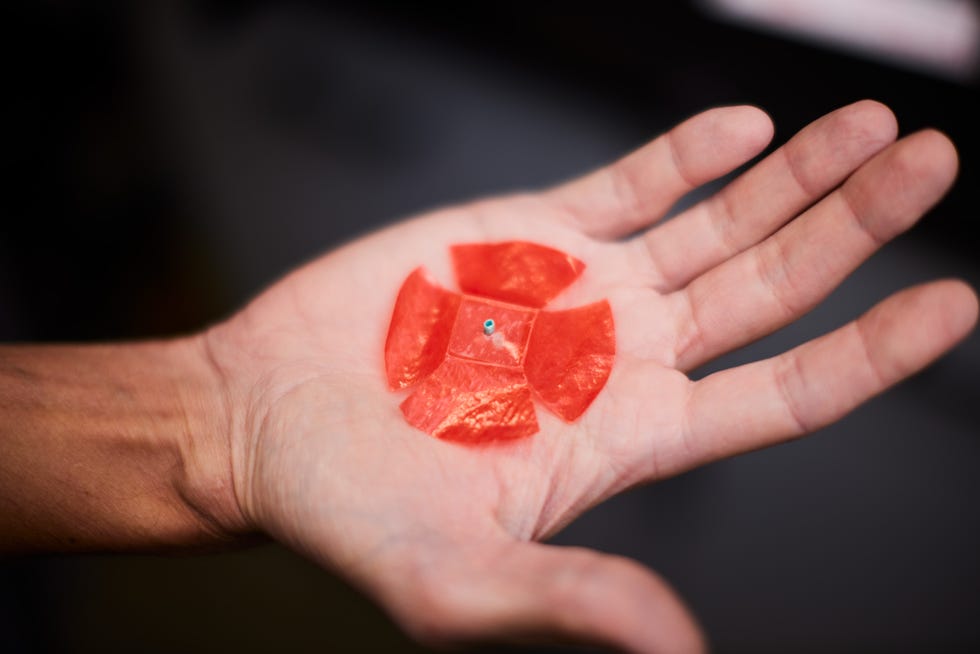

The push to develop low-cost and low-impact alternatives to traditional aircraft has grown in recent decades. For example, in 2017 the San Francisco–based research and development firm Otherlab announced it had won a grant from the Defense Advanced Research Projects Agency (DARPA) to work on a lightweight cardboard glider that could someday deliver blood, vaccines, or other critical cargo to remote locations inaccessible via other modes of transportation.

The gliders, constructed from flat-packed pieces of cardboard, would be released from an airplane and, with the help of an onboard computer, navigate to a preprogrammed set of coordinates. Otherlab and DARPA shelved the project, but the central idea—tapping into the realm of unpowered flight to solve difficult problems—lives on.

Future small aircraft may also veer away from mimicking airplanes altogether, Wang says. In addition to studying paper gliders, much of her research focuses on forms of passive flight and gliding we already find in nature, such as insects and seeds that twirl off tree limbs. Using these techniques to create small craft could create even more possibilities in years to come.

Even after locating a glider’s center of mass, Wang cautions that this discovery won’t necessarily make solving future problems facing paper craft experts or engineers any easier. She and colleagues are attempting to solve these problems mathematically. Applying these mathematical revelations to a working glider? Well, that’s another challenge entirely.

Advertisement – Continue Reading Below

Paper airplane enthusiasts, she suggests, might have better luck crafting gliders using intuition and experimentation instead. “People can make very, very good paper airplanes now,” Wang says. “It’s a fine art. They build their intuition by making them.”

Suzuki, Toda, and their collaborators spent 18 months testing multiple designs. They coated each plane in a protective glasslike substance that would raise the heat resistance but still allow for crisp, complex folds. With this design, Suzuki hoped that they might be able to test applications for other small-scale reentry vehicles.

The team then tested a prototype glider in the University of Tokyo’s hypersonic wind tunnel, subjecting the plane to speeds as high as Mach 7 and temperatures of almost 450°F—conditions similar to those a paper plane might face when reentering Earth’s atmosphere.

With these tests under their belt, the team reached out to Japan Aerospace Exploration Agency, who agreed to fund the project. One of the agency’s astronauts, Koichi Wakata, even expressed interest in launching them from the orbiting outpost himself. Ultimately, due to budget cuts, Suzuki and Toda’s paper planes never made it to space.

As researchers explore the field of aerodynamics, and new technology continues to model this type of flight, there’s still a chance we could see paper gliders pushing boundaries in years to come.

August 6th 2023

| Ribblehead ViaductBuilt 1870 – 1875 Grade II Listed Part of the Settle-Carlisle Conservation AreaThe Ribblehead Viaduct carries the Settle-Carlisle Railway across Batty Moss  Photograph used with permission of Settle Photographic Group. Designed by John Sydney Crossley (Chief Engineer of the Midland Railway), the viaduct is the longest and third tallest structure on the Settle-Carlisle line.The Viaduct has twenty-four magnificent arches that carry the railway line 104 ft above the moor.Two thousand three hundred men (navvies) were involved in the construction of the viaduct and the nearby Blea Moor tunnel.The navvies lived in shanty towns built in the area near the base of the viaduct. This area is now a Scheduled Ancient Monument.Over 100 men died during the construction of the viaduct. https://www.google.com/maps/d/u/0/embed?mid=1wejqu-1QcJ9nlcdMEdtqusXQQZ52j0mZ  Steam Train on Ribblehead Viaduct (Photograph used with permission of Settle Photographic Group)  Ribblehead Viaduct with Ingleborough in the background (Photograph used with permission of Michael Cardus) Ribblehead Viaduct with Whernside in the background (Photograph courtesy of Where2Walk) https://www.youtube.com/embed/7SuiLrdlHP8 https://www.youtube.com/embed/uia1vSrX1BE WALKS…Ribblehead – a short walk“The Ribblehead viaduct is one of the most impressive engineering projects in England. It is also sat in wonderful scenery and this short Ribblehead walk will do it full justice. The extension to Blea Moor tunnel only adds to it.”Route details at where2walk.co.uk Whernside from Ribblehead“The climb of Whernside from Ribblehead is one of the most popular walks in the Yorkshire Dales. Any walk combining the superb viaduct at Ribblehead with the highest point in Yorkshire must be good.”Route details at where2walk.co.uk FIND OUT MORE …exploremoresettlecarlisle.co.ukhistoricengland.org.uk NEARBY … |

| Site Go Top Disclaimer Site MapBecome a Vibrant Settle Business Partner 2023 Advertising Options, Rate Card & Order Form 2023 Welcome to the Settle Area’ GuideAbout Vibrant Settle About Vibrant SettleContact Contact Us © 2023 Vibrant Settle Community Partnership eCommerce Software by Bluepark |

| Welcome to the Settle |

Designed by John Sydney Crossley (Chief Engineer of the Midland Railway),

the viaduct is the longest and third tallest structure on the Settle-Carlisle line.

The Viaduct has twenty-four magnificent arches that carry the railway line 104 ft above the moor.

Two thousand three hundred men (navvies) were involved in the construction of the viaduct and the nearby Blea Moor tunnel.

The navvies lived in shanty towns built in the area near the base of the viaduct.

This area is now a Scheduled Ancient Monument.

Over 100 men died during the construction of the viaduct.

https://www.google.com/maps/d/u/0/embed?mid=1wejqu-1QcJ9nlcdMEdtqusXQQZ52j0mZ

Steam Train on Ribblehead Viaduct

(Photograph used with permission of Settle Photographic Group)

Ribblehead Viaduct with Ingleborough in the background

(Photograph used with permission of Michael Cardus)

Ribblehead Viaduct with Whernside in the background

(Photograph courtesy of Where2Walk)

March 30th 2023

Aboard the Giant Sand-Sucking Ships That China Uses to Reshape the World

Massive ships, mind-boggling amounts of sand, and an appetite for expansionism in the South China Sea: the recipe for a land grab like no other.

- Vince Beiser

Read when you’ve got time to spare.

Advertisement

More from MIT Technology Review

- Ghost ships, crop circles, and soft gold: A GPS mystery in Shanghai

- A new generation of AI-powered robots is taking over warehouses

- China is racing ahead in 5G. Here’s what that means.

Advertisement

CSIS Asia maritime transparency initiative / DigitalGlobe.

Fifteen miles out on the water south of Biloxi, Mississippi, below a cloudless sky, a foaming torrent of gray-black slurry gushes into a ship. Every three seconds, another truckload’s worth of salt water and sand, siphoned from the bottom of the Gulf of Mexico, pours into the Ellis Island’s vast, open cargo hold, called a hopper. The ship is gargantuan—the biggest such dredge ever built in the United States. Its progress is, by design, slow. It is hauling a pair of 30-ton drag heads, studded with steel teeth, which scrape along the sandy sea bottom. Twin pipes, each three feet (90 centimeters) in diameter, connect the drag heads to giant pumps on the ship’s deck. The pumps suck slurry into the hopper, which slowly fills with roiling gray soup, speckled with muculent, softball-size bubbles.

“We call ourselves dirt merchants,” Gabriel Cuebas, the Ellis Island’s captain, told me when I visited on a hot day in October 2018. His ship is 433 feet (132 meters) long—a good bit longer than an American football field and about half the length of an aircraft carrier. Twin yellow cranes perch on either side of the deck. Their metal bulk towers over a maze of catwalks and pipes that surround the hopper.

It takes several hours for the hopper to fill with slurry. Once that is done, enormous winches haul up the drag heads, and the ship sets course toward the mainland. An hour or so later, the Ellis Island drops anchor several miles offshore, in water deep enough for its 30-foot draft. An assembly that looks like an eyeless robotic sea serpent bobs in the waves. Crew members get a rope around the serpent’s head and winch it out of the water. They connect the serpent to a pipe leading from the hopper. The ship’s pumps kick in again, pulling slurry back out of the hopper and shooting it down a mile of pipe to a floating booster station, where more pumps will usher it along. The sand will travel through almost five miles (eight kilometers) of pipe before it is finally blasted onto the shore of Ship Island.

Ship Island is, for the moment, actually two islands. What was originally its center was eroded by hurricanes: Camille in 1969 and Katrina in 2005. (It was spared the worst of 2018’s Hurricane Michael.) The US Army Corps of Engineers, the federal agency charged with maintaining America’s waterways, has hired the Ellis Island to help rebuild the eight-mile-long island, an important bulwark against increasingly severe storm surges.

Once this load of sand has been discharged, the Ellis Island will head back out for another, and then another, around the clock, day after day. The whole job will take about a year, during which a relay of ships will move enough sand to bury the real Ellis Island 50 yards deep: 7 million cubic yards (5.4 million cubic meters) of it. The total cost of rebuilding Ship Island, to be paid by the federal government, will be some $350 million.

The Wan Qing Sha, a trailing suction hopper dredger, helps build a new city off the coast of Colombo as part of a massive Chinese infrastructure project, the largest foreign investment in Sri Lanka’s history. Photo credit: ISHARA S. KODIKARA / AFP / Getty Images.

It is a colossal operation. But compared with what China is doing, it’s a drop in the ocean.

In China as elsewhere, dredging is used to build protective barriers against the rising seas, as the Ellis Island is doing, and to create valuable new real estate. But for China’s president, Xi Jinping, it is also an important geopolitical tool. Today, more than ever, dredges have the power to create land where there was none, altering the shapes of coastlines and the contours of countries. No nation has cultivated this power more zealously than China.

In recent years, China has assembled an armada of oceangoing dredges. Some it buys from Japan, Belgium, and the Netherlands. Increasingly, though, China manufactures them itself. China’s homemade dredges are not yet the world’s largest, nor are they any more technologically advanced than those of other countries, but it is building many more of them than any other country. In the past decade, Chinese firms have built some 200 vessels of ever greater size and sophistication. In 2013, Rabobank, a Dutch firm, declared that China’s dredging industry had become the biggest in the world, and it has only grown since then. Chinese firms bring in as much revenue from domestic dredging as is accrued in all of Europe and the Middle East combined.

Since 1985, according to Deltares, a Dutch research group, humans have added 5,237 square miles (13,564 sq km) of artificial land to the world’s coasts. China is a major—and growing—contributor to that total.

Most plant and animal life on the seven Spratly reefs was destroyed by the mountains of sand dumped atop the coral.

In 2015 alone, China created the equivalent of nearly two Manhattans of new real estate. In recent years, it constructed two artificial islands to support a 34-mile-long bridge that connects Hong Kong with Macao and the Chinese mainland; it opened in October 2018 and is the world’s longest sea crossing. Much of that work was carried out by state-owned CCCC Dredging, the world’s largest dredging firm. By way of comparison: In 2017, Great Lakes Dredge and Dock, America’s biggest, took in an estimated $600 million from dredging operations. CCCC Dredging booked $7 billion.

Manufacturing land is not a new practice. The Dutch have been creating new territory since the 11th century by damming wetlands and pumping them dry. Peter Stuyvesant, the first governor of what would come to be called Manhattan, expanded the island with earth displaced by the construction of buildings and canals. Land reclamation, as the practice is called even when the “reclaimed” land is entirely new, has long gone hand in hand with dredging’s other main purpose—clearing paths for ships to travel in.

Today the industry’s basic tool is the centrifugal pump. It is something like a blender bisected by a garden hose. A motorized drive shaft spins an impeller. The impeller’s spin pulls liquid (and sand) through the pipe. First introduced in the 1860s, these pumps enormously increased the amounts of sediment that can be siphoned from the ground under the sea. They also make it possible to pump the stuff through miles of pipeline to distant destinations.

As steam power gave way to diesel in the late 19th century, the size and power of dredges grew. Developers in Los Angeles used centrifugal pumps to expand the city’s port and turn marshlands into seaside real estate. Sediment dredged from underwater built Boston’s Back Bay, as well as large portions of Marseilles, Mumbai, and Hong Kong.

Beginning in the 1970s, oil-exporting countries in the Persian Gulf plowed their surging wealth into developing huge new ports, which spurred dredging companies to bring larger, mightier ships to market. For coastal megalopolises long on population but short on waterfront, land reclamation offers a way to add room. Hong Kong and Osaka, Japan, both built new international airports on artificial islands in the 1990s. Many of the world’s largest artificial islands are either in the Middle East, such as Dubai’s famous palm-tree-shaped islands, or off the coast of Japan. But that is changing.

The Chinese government declared dredging a “priority growth area” in 2001, as part of a push to increase China’s maritime power. At the time, the country’s dredging fleet consisted of aging, outdated ships. Chinese companies were capable of building only relatively small vessels. With the government’s support and investment, capabilities boomed. In the past 15 years, Chinese companies have built scores of the main types of giant dredges: trailing suction hopper dredgers—“trailers” for short—and cutter suction dredgers.

Trailers like the Ellis Island gather sand while on the move. Their drag heads break up loosely compacted sea-bottom sands, which are then vacuumed up and stored in the ship’s hoppers for transport. In 1965, the biggest such dredges could hold about 6,500 cubic yards of material. That number more than tripled by 1994; by now, it has grown nearly tenfold. The world’s two biggest dredges, the Cristóbal Colón and the Leiv Eiriksson, were built in Spain for Belgium’s Jan De Nul Group in 2009 and 2010. They are identical twins. Stood on end, each would rise higher than a 60-story skyscraper. They can carry about four times as much sludge as the Ellis Island.

Cutter suction dredgers, meanwhile, anchor in areas where the sea bottom is too hard for trailers. A boom arm capped with a cutter head—a tooth-studded steel ball the size of a wine barrel—protrudes from the bottom of the ship. The ball spins around, tearing up sand, rocks, and whatever else it finds on the seabed, while a suction line behind it hoovers up the grains. The material is then pumped onto a barge, or sometimes straight into a pipe leading to the land reclamation site. Cutter suction dredgers’ might is measured by their installed electrical power, which has also grown exponentially in recent decades. The most potent generate and consume more than 40 megawatts—enough to power 30,000 American homes.

In 2017, CCCC Dredging launched the Tian Kun Hao, Asia’s biggest cutter suction dredger, which was built entirely in China. It is about the same size as the Ellis Island, or about a quarter the size of the Belgian behemoths, and can suck nearly 8,000 cubic yards of sand and other material per hour from depths up to 100 feet.

CCCC Dredging has begun taking on projects overseas, and it now operates in dozens of countries. It has a particular focus on places targeted for Chinese-led port development as part of Xi’s Belt and Road Initiative.

China’s land reclamation work will have tremendous economic consequences in coming years. Its political consequences are already profound.

The South China Sea is one of the world’s busiest shipping routes. What’s more, billions of barrels of oil and trillions of cubic feet of natural gas lie under the seafloor. So it’s no surprise that every country in the region—China, Taiwan, Vietnam, Brunei, Malaysia, and the Philippines—lays claim to parts of the Spratly Islands, a scattering of rocks and reefs in the middle of the sea, 500 miles due east of Vietnam and 200 miles southwest of the Philippines.

China controls seven naturally occurring Spratly outcroppings (one of which it seized from Vietnam in a 1988 clash that left dozens of soldiers dead). It is using its industrial might to create new facts in the water. Starting in late 2013, the Chinese government set dozens of CCCC Dredging’s ships to work. Within 18 months, these ships added nearly 3,000 acres (1,200 hectares) of new land to the Spratlys, enough to fit three copies of New York’s Central Park with room to spare.

Almost as soon as the sand was dry, China began turning the new islands into military bases. It installed antimissile weaponry, runways capable of handling military aircraft, structures apparently designed to house long-range surface‑to‑air missile launchers, and port facilities for warships. China has also built new territory in another tiny collection of South China Sea islands called the Paracels, where it has similarly installed airstrips and missile batteries.

This expansion of Chinese power into the Pacific has alarmed the US as well as China’s neighbors. To show it does not recognize the new islands as Chinese territory, the United States has made a point of flying B-52 bombers over them and sending warships to pass close by. For its part, China has landed long-range bombers on its new runways, as a show of force.

Ships congregate just northeast of Fiery Cross Reef. CSIS Asia maritime transparency initiative / DigitalGlobe.

Tensions spiked in late September 2018, when the Lanzhou, a Chinese destroyer, cut across the bow of the USS Decatur, an American destroyer. The Decatur’s captain slammed the ship’s engines into reverse, averting a collision by only 45 yards—a quarter of the length of his ship. The incident took place just a few miles away from some of the new artificial islands.

It may be too late for other nations to do much about China’s artificial-land grab. Admiral Philip S. Davidson, head of the US Indo-Pacific Command, told Congress in April (shortly before assuming his command) that “China is now capable of controlling the South China Sea in all scenarios short of war with the United States.”

All that island building has also caused “devastating and long-lasting damage to the marine environment,” according to the Hague-based Permanent Court of Arbitration, which rejected China’s claim to sovereignty over much of the South China Sea in 2016. Most plant and animal life on the seven Spratly reefs was destroyed by the mountains of sand dumped atop the coral. John McManus, a University of Miami marine biologist, called it “the most rapid rate of permanent loss of coral reef area in human history.”

Other land reclamation projects have inflicted similar, albeit smaller-scale, damage. They have destroyed or damaged coral reefs and oyster and seagrass beds in Dubai, Bahrain, and other Gulf countries, as well as killing marine life. In the US, dredges are required to make sure they’re not sucking up turtles and other sea creatures; if they do, they have to stop work until they address the problem. Environmental concerns are one reason why, while China is feverishly building new land, land reclamation in the US is just what it sounds like—confined almost exclusively to counteracting the erosion of previously existing land. “In Bahrain, if we found a turtle we’d just throw it back over the side,” says Brian Puckett, a Great Lakes executive who oversees the Ship Island project.

Puckett is proud to show off pictures of the islands he helped create for real estate developers in the Persian Gulf. “It’s amazing to be able to show them to people on Google Earth and say, ‘I built that,’” he says. “That was part of the reason I came to work with Great Lakes. I want to work on projects that are important.”

Island building, as China has shown, is one of the most important projects there is. Today, geopolitical power goes not only to those who control territory but to those who can manufacture it.

Vince Beiser is the author of “The World in a Grain: The Story of Sand and How It Transformed Civilization.” Reporting for this article was supported by the Pulitzer Center on Crisis Reporting.

Copyright © 2018. All rights reserved MIT Technology Review; www.technologyreview.com.

March 5th 2023

Who Invented Steel?

by Team Miracle Truss | Dec 10, 2019 | Strong & Flexible Buildings

We know that Thomas Edison invented the lightbulb, the Wright brothers invented the first practical airplane, and Guglielmo Marconi invented the radio. But can we trace back the invention of steel to a single individual?

Due to how long we’ve been using steel, that’s not possible. Steel production can be traced back nearly 4,000 years to the start of the Iron Age. The earliest examples have been dated to about 1800 BC. Here’s a rough timeline.

13th Century BC

The earliest evidence of steel production can be traced back to this time. Blacksmiths found – by accident – that iron became stronger, harder, and more durable when the carbon found in coal furnaces was added to iron. The next upgrade came in about the 6th Century BC, when craftsmen in southern India used crucibles to smelt iron with charcoal. It’s often called wootz steel.

3rd Century AD

The first mass production of steel is credited to China. It’s believed that they used techniques similar to what’s known as the Bessemer Process, in which blasts of air were used to remove impurities from the molten steel.

One of the best examples of steel in architecture during this time is the Iron Pillar of Delhi, which stands 24 feet tall, and is one of the oldest examples of the rust-resistant qualities of steel.

The 1700s

For the first time in 1702, coke was used in the mass production of steel – rather than charcoal. The next big leap in steel production came in 1740, when English inventor Benjamin Huntsman developed the crucible steel technique. Ironically, his own countrymen didn’t care much for the hardness of the steel Huntsman produced, so his biggest customer became the country of France.

The 1800s

One of the most important points in the history of steel production happened in 1855, when English engineer henry Bessemer ushered in the ability to mass produce steel inexpensively by removing impurities by blowing air through the molten iron. The result was much stronger steel, and it led to the construction of the first steel suspension bridge – which we know today as the Brooklyn Bridge.

The Use of Steel in Construction Today

Steel’s resistance to rust and its natural strength make it the perfect substitute for more traditional framing material used in construction such as wood. Our Miracle Truss® DIY building kits utilize steel in the clear span truss designs to give owners maximum interior space. The trusses allow wall heights of 30 feet or more, as well as building widths of more than 125 feet – all without any interior pole supports. Check out our current building specials!

February 21st 2023

Boeing Boeing Boeing Gone.

The 1,574th and final 747, which rolled off Boeing’s production line in Everett, Washington, on January 31, is destined for a life shipping goods around the world on behalf of the New York–based cargo company Atlas Air.

It’s an unremarkable end to an era of aviation that began more than half a century ago. The first 747—“the airplane that ‘shrank the world’ and revolutionized travel,” according to Stan Deal, president and chief executive officer of Boeing Commercial Airplanes—was unveiled in 1968. Since then, the aircraft has clung on as a workhorse for airlines around the world and as an emblem for a lost “golden age” of air travel, despite long being surpassed by newer, better planes. “Technology has moved on,” says John Strickland, an aviation analyst at JLS Consulting.

This is at least the second time that the 747’s obituary has been written. Orders for the aircraft peaked at 122 in 1990, and have been in decline ever since. The last passenger 747 was delivered to Korean Air in 2017. In 2020, Qantas and Virgin flew their last passenger flights using the plane, and British Airways announced it would be phasing the model out—four years earlier than expected. According to aviation data analytics group Cirium there are still 385 747s still in service, mostly working for cargo companies, and 122 in storage. The company projects that there will still be close to 100 747s in service in 2040.

“The falling out of favor of the 747 has been a gradual process,” says Brendan Sobie, founder of Singapore-based aviation consulting company Sobie Aviation.

The 747’s early appeal was partly down to its sheer size. In the 1950s and 1960s, most planes were narrow-body, single-aisle jets that could only fit a comparatively small number of passengers. The 747’s four engines meant that the size of the plane itself could be far larger, and with that, more seats and galley space, too. “Airlines were worried initially about how they were going to manage to sell all these additional seats on the aircraft,” Strickland says. “But it gave them a chance to sell more competitively and more excessively at the bottom end of the range, as well as still offering incredible service at the top end.

“It’s just a big aeroplane,” says Robert Mann, an aviation analyst at New York–based RW Mann & Company. “It’s not just voluminous. It’s like a concert hall on wings. It’s a palatial experience.”

Featured VideoNeurosurgeon Answers Brain Surgery Questions From Twitter

Most Popular

- BusinessHeat Pumps Sell Like Hotcakes on America’s Oil-Rich FrontierChris Baraniuk

- BusinessWorkers Are Dying in the EV Industry’s ‘Tainted’ CityPeter Yeung

- SecurityHow to Unlock Your iPhone With a Security KeyDavid Nield

- GearGive Your Back a Break With Our Favorite Office ChairsJulian Chokkattu

That scale came with an awe factor, which, in a competitive industry where passengers increasingly had a choice of airlines, was a significant selling point. “No matter who was operating it, whether it was Japan Airlines or Lufthansa, British Airways, Air France, or a government entity, it projected power,” Mann says. “It was an airplane that was an outsize projection of power. People stood there in amazement.”

The plane’s engines, which produce 45,000 pounds of thrust, represented a significant advancement over a previous generation of aircraft. But they were soon surpassed by newer technologies. Later engines would produce up to 100,000 or 120,000 pounds of thrust, meaning planes only needed two engines rather than the 747’s four. “And you needed less fuel to do the same mission as the 747,” says Mann.

Modern airlines need to reckon with rising fuel costs, a competitive environment that demands ever greater efficiency, and carbon emissions. A Boeing 747-400, which was manufactured between 1989 and 2009, costs around $26,635 an hour to run. A Boeing 787-8, which is still produced today, costs $14,465 an hour to operate—45 percent cheaper.

Mann points out that even Atlas Air, which is taking the last 747 to be made, has already started moving the bulk of its cargo business to the Boeing 777, a twin-engined plane that entered service in the mid-1990s. “It’s not even a toss-up anymore,” says Mann. “You want to be using the Boeing 777… [the 747] has become something relatively obsolete,” says Sobie.

For passenger flights, the plane is doubly obsolete. The 747, with its ability to seat more than 500 passengers at maximum capacity, doesn’t reflect the current market for air travel. Many travelers make shorter journeys than the long-haul, transatlantic trawls the 747 was designed for, meaning airlines need smaller, single-aisle planes.

In an industry still struggling to recover from the impact of the Covid pandemic, making sure you have the right-size jet for the right route matters more than ever. Cirium data shows that Covid wiped $220 billion from the aviation industry’s balance sheet. In the first six months of the pandemic, 43 airlines closed because of the slump in travel.

Smaller, single-aisle jets are expected to account for seven in every 10 aircraft delivered to airlines in the next two decades, according to Cirium. Already, the single-aisle market is worth more to manufacturers, at $1.6 trillion a year, than the $1.1 trillion twin-aisle market. Both Boeing and Airbus are devoting more space at their production facilities to smaller, single-aisle aircraft rather than the larger, twin-aisle jets they were initially designed for.

“From the passenger perspective, things have shifted more toward twin-engine, wide-bodied planes that are extremely efficient and have better economics for airlines,” says Sobie.

However, all of those issues have been known about for decades. The aviation sector has been seeking greater financial and fuel efficiencies for years, and new technology managed to surpass the 747 almost the moment it took off on its first flight. The reason that technical, financial, and commercial considerations have until now not spelled the end of the 747 is down to the model’s central role in people’s mind when they think of air travel.

For Strickland, it was one of the first planes he saw—at a time when it was being tested, and so it still holds a place in his heart. For Mann, the admiration for the 747 resulted in him stopping a car near the Arc de Triomphe in Paris in order to snap a photograph of it flying over the city’s monument.

The 747 was aviation in many people’s minds, and was that for the best part of five decades. It represented the key firmament of people’s perception of what air travel was, and should be. But, says Mann, “the golden age of air travel is what you make it.”

Here’s How Your Car’s Engine Works

This is how the combination of an engine, fuel, and air makes your car move, explained in plain English, in case you’re not an engineer.

- K.C. Colwell

The major difference between these two is how energy is created. In diesel engines, the air is compressed before the fuel is injected. In petrol engines, gas and air are mixed, and then compressed and ignited. Another difference is, of course, in the type of fuel used.

What Is The Difference Between Diesel And Petrol Engines?

https://www.valvoline.com › … › Useful Resources

Photo by Getty Images

For most people, a car is a thing they fill with gas that moves them from point A to point B. But have you ever stopped and thought, How does it actually do that? What makes it move? Unless you have already adopted an electric car as your daily driver, the magic of how comes down to the internal-combustion engine—that thing making noise under the hood. But how does an engine work, exactly?

Specifically, an internal-combustion engine is a heat engine in that it converts energy from the heat of burning gasoline into mechanical work, or torque. That torque is applied to the wheels to make the car move. And unless you are driving an ancient two-stroke Saab (which sounds like an old chain saw and belches oily smoke out its exhaust), your engine works on the same basic principles whether you’re wheeling a Ford or a Ferrari.

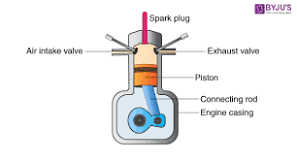

Engines have pistons that move up and down inside metal tubes called cylinders. Imagine riding a bicycle: Your legs move up and down to turn the pedals. Pistons are connected via rods (they’re like your shins) to a crankshaft, and they move up and down to spin the engine’s crankshaft, the same way your legs spin the bike’s—which in turn powers the bike’s drive wheel or car’s drive wheels. Depending on the vehicle, there are typically between two and 12 cylinders in its engine, with a piston moving up and down in each.

Where Engine Power Comes From

What powers those pistons up and down are thousands of tiny controlled explosions occurring each minute, created by mixing fuel with oxygen and igniting the mixture. Each time the fuel ignites is called the combustion, or power, stroke. The heat and expanding gases from this miniexplosion push the piston down in the cylinder.

Almost all of today’s internal-combustion engines (to keep it simple, we’ll focus on gasoline powerplants here) are of the four-stroke variety. Beyond the combustion stroke, which pushes the piston down from the top of the cylinder, there are three other strokes: intake, compression, and exhaust.

Engines need air (namely oxygen) to burn fuel. During the intake stroke, valves open to allow the piston to act like a syringe as it moves downward, drawing in ambient air through the engine’s intake system. When the piston reaches the bottom of its stroke, the intake valves close, effectively sealing the cylinder for the compression stroke, which is in the opposite direction as the intake stroke. The upward movement of the piston compresses the intake charge.

The Four Strokes of a Four-Stroke Engine

Photo by Getty Images

In today’s most modern engines, gasoline is injected directly into the cylinders near the top of the compression stroke. (Other engines premix the air and fuel during the intake stroke.) In either case, just before the piston reaches the top of its travel, known as top dead center, spark plugs ignite the air and fuel mixture.

The resulting expansion of hot, burning gases pushes the piston in the opposite direction (down) during the combustion stroke. This is the stroke that gets the wheels on your car rolling, just like when you push down on the pedals of a bike. When the combustion stroke reaches bottom dead center, exhaust valves open to allow the combustion gases to get pumped out of the engine (like a syringe expelling air) as the piston comes up again. When the exhaust is expelled—it continues through the car’s exhaust system before exiting the back of the vehicle—the exhaust valves close at top dead center, and the whole process starts over again.

In a multicylinder car engine, the individual cylinders’ cycles are offset from each other and evenly spaced so that the combustion strokes do not occur simultaneously and so that the engine is as balanced and smooth as possible.

Photo by Getty Images

But not all engines are created equal. They come in many shapes and sizes. Most automobile engines arrange their cylinders in a straight line, such as an inline-four, or combine two banks of inline cylinders in a vee, as in a V-6 or a V-8. Engines are also classified by their size, or displacement, which is the combined volume of an engine’s cylinders.

The Different Types of Engines